Real-time VDP Collation Function

Overview

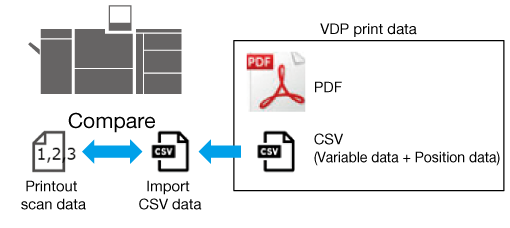

This function automatically inspects whether or not variable printing of numeric values or barcodes is performed correctly by collating the CSV file of VDP print data with the actual printout in real-time.

- The following optional unit is required to use the Variable Data Inspection function.

- Variable Data Inspection Kit UK-312

- You can only perform the VDP data comparison without the automatic inspection.

- The automatic inspection can be combined with the Variable Data Inspection function.

Procedure (Preparing the CSV File to Collate)

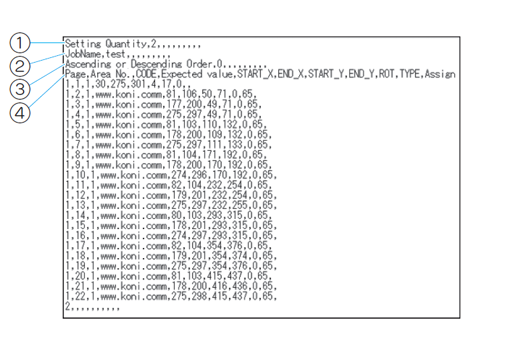

No. | Name | Description |

|---|---|---|

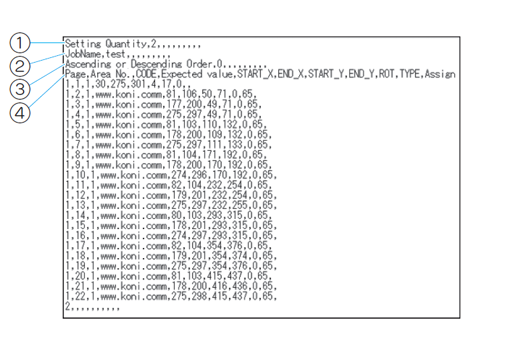

1 | Setting Quantity | Number of setting items related to the entire job. Select the required items from the following: JobName and Ascending or Descending Order. To only set "Ascending or Descending Order", type "1". To set both, type "2". |

2 | JobName | Job name. Symbol \ is handled as _. |

3 | Ascending or Descending Order | Order in which the numeric value varies. 0: Ascending order 1: Descending order This item is required to set. |

4 | Page | The page number(s) that will be used for comparisons. Set any pages between 1 and 200,000. If either Image Controller IC-317 or Image Controller IC-419 is mounted, the scan image in Intelligent Quality Optimizer IQ-501 is used as the reference image (for 1 output sheet, the front page is counted as the first page and the back side is counted as the second page). |

Area No. | Area No. Set in the range from 1 to 30. | |

CODE | Code type. Set "0" or "1". 0: Number only 1: Barcode (including 2D code) | |

Expected value | Expected decoding result. If the read value matches this value, it is assumed that there is no problem. Enter a UTF-8 character string such as -, +, $, /, ., %, and space, excluding a comma (,). If the value is blank, it is skipped without being collated. | |

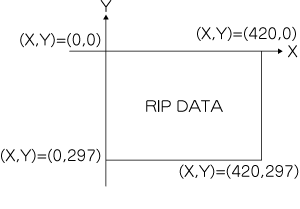

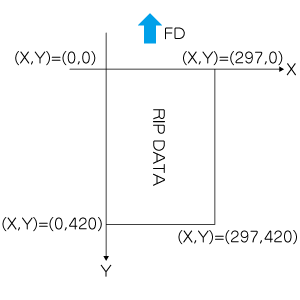

START_X | Starting point of X coordinate. Set in the range from 0 to 330 (units of 1 mm). Set the top direction as the top and the upper left as the origin reference on the original (RIP) image, and specify the XY coordinates.  If either Image Controller IC-317 or Image Controller IC-419 is mounted, specify the XY coordinates by setting the delivery direction as the top direction and the upper left as the origin reference based on the scan image in Intelligent Quality Optimizer IQ-501.  | |

END_X | Ending point of X coordinate. Set in the range from 1 to 331 (units of 1 mm). | |

START_Y | Starting point of Y coordinate. Set in the range from 0 to 487 (units of 1 mm). | |

END_Y | Ending point of Y coordinate. Set in the range from 1 to 488 (units of 1 mm). | |

ROT | Image orientation in decoding area. 0: Upward 1: Leftward 2: Downward 3: Rightward | |

TYPE | The following types are available. 1: Code 39 2: Code 128 3: JAN(EAN) 5: ITF 6: NW-7 7: Code 93 8: UPC 18: GS1-128 65: QR Code 66: PDF417 67: Aztec Code 68: Data Matrix ECC 200 Data Matrix ECC 200 performs decoding only for Variable Data Inspection. The barcode inspection of the automatic inspection function is not available. | |

Assign | Assign Leave this item blank. |

- To edit a CSV file using spreadsheet software, set the character code to UTF-8 before saving.

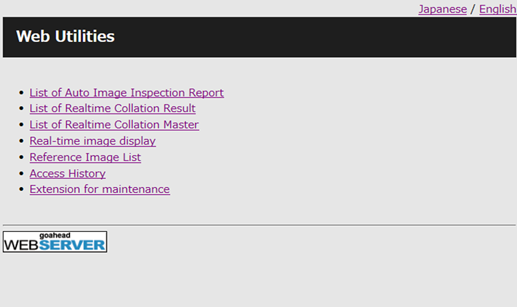

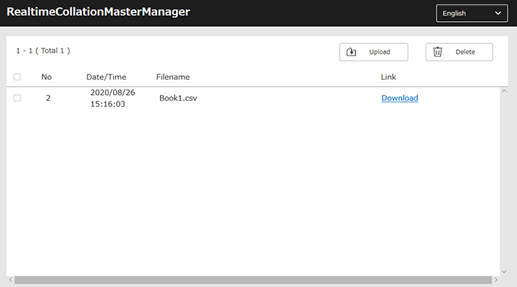

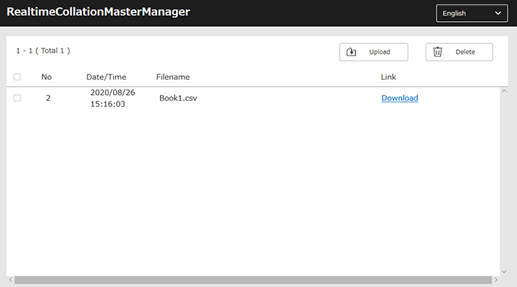

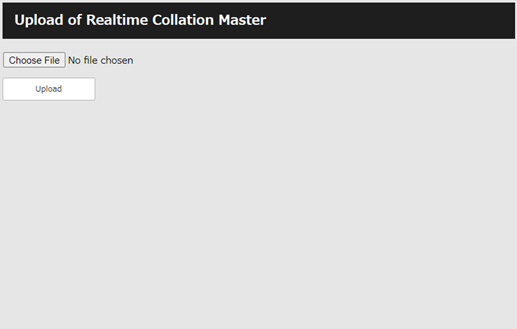

Procedure (Uploading a CSV File)

- To upload a CSV file using the Microsoft browser such as Internet Explorer or Edge, open the Security tab in [Internet Options], and set [Include the path of the local directory when uploading a file to the server] in [Custom Level] to [Disable]. If this setting is not changed, it may cause an upload failure.

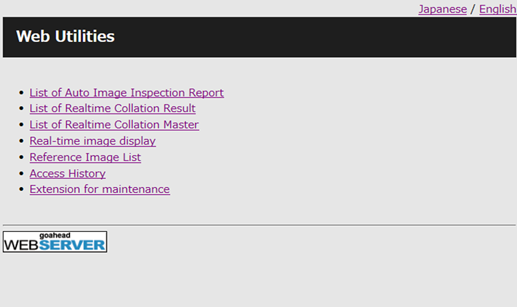

For details about the operating environment of the Web Utilities browser, refer to What Is Web Utilities?.

"http://<IP address of Auto Inspection Unit UK-301>/"

For example, if the IP address of UK-301 is 192.168.1.20, enter "http://192.168.1.20/".

- The IP address of Auto Inspection Unit UK-301 must be set first using [Auto Inspection NIC Setting].

The Web Utilities top screen for Auto Inspection Unit UK-301 is displayed.

The selected CSV file is uploaded to this machine.

Procedure (Holding a Print Job before Execution)

Execute a job, and collate the expected decoding result entered in the CSV file with the printout.

For details on the procedure, refer to Creating New Reference Images and Performing Automatic Inspections or Selecting Pre-Created Reference Images and Performing Automatic Inspections.

- The settings related to the automatic inspection are not required if the automatic inspection is skipped.

- [File Name] of the executed print job must completely match the CSV file name. If an extension such as [File Name] includes an extension such as "xxxxx.pdf", is included in the file name, the real-time VDP collation cannot be performed.

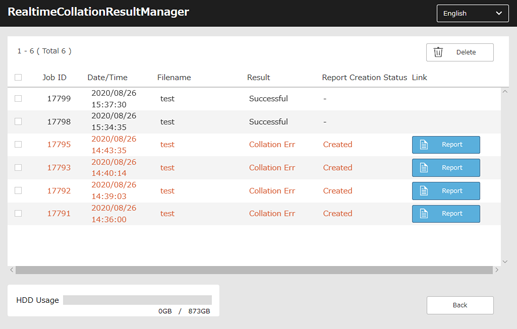

Procedure (Checking the Collation Result After the Job is Complete)

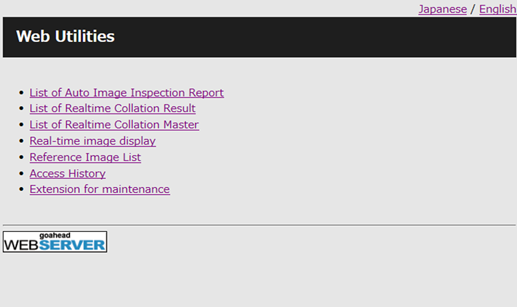

For details about the operating environment of the Web Utilities browser, refer to What Is Web Utilities?.

"http://<IP address of Auto Inspection Unit UK-301>/"

For example, if the IP address of Auto Inspection Unit UK-301 is 192.168.1.20, enter "http://192.168.1.20/".

- The IP address of Auto Inspection Unit UK-301 must be set first using [Auto Inspection NIC Setting].

The Web Utilities top screen for Auto Inspection Unit UK-301 is displayed.

The List of Realtime Collation Result screen is displayed.

The Mismatch Report screen is displayed.

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.