Adjustment: Image Position

About Adjusting the System's Image Position

1 issue that can commonly occur during printing is the image position misalignment.

The accuracy of the image position can differ depending on the ambient temperature or humidity, the condition of the system, and the texture of the paper type used. The image position should be regularly adjusted in order to achieve stable accuracy when it comes to image positioning.

"Image Position Adjustment" is a function used for adjusting the position where an image is placed during printing. When performing 1-sided printing, adjust the printing position on the front side so that the image is placed in the desired position. When performing 2-sided printing, adjust the image position on the front and back sides of the paper so that there is as little deviation between the two sides as possible.

Checking the Reference Position on the System

When performing Image Position Adjustment, be sure to first adjust the reference position to determine the correct image printing position. For details about the various functions, refer to the reference page.

- The adjustment of printing surface reference positions is an advanced adjustment. Contact your service representative before making any adjustments.

Function | Description |

|---|---|

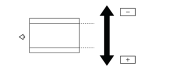

Adjust the image lead-edge position (image writing position) in the paper feed direction when printing. Set it so that the printing starts from the correct position. | |

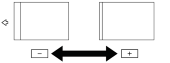

Adjust the image centering in the crosswise direction when printing. Check for any misalignment between the center in the paper feed direction and the center of the image, and then make adjustments so that the image is printed in the correct position. | |

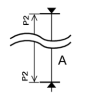

Adjust the magnification in the paper feed direction when printing. Adjust accordingly so that the chart test pattern is printed correctly. | |

Adjust the magnification in the crosswise direction when printing. Adjust accordingly so that the chart test pattern is printed correctly. |

Performing Image Position Adjustments

Configure the reference position on the system before performing Image Position Adjustment.

Adjustments should be made during the times detailed below. There are different adjustment workflows for the various times where adjustment is required. For details about the various adjustment workflows, refer to the reference page.

Adjustment Timing | Adjustment Workflow Type |

|---|---|

After powering on the system | |

At user discretion during use of the system | |

When finishing adjustments are required after executing a job |

- Using "Paper Profile"

If you have made adjustments to paper of a new type, weight, or size, register the adjustment results on the system as a paper profile. Then, the next time when you make a print using the same paper conditions, you can use this paper profile to make the paper setting process more efficient.

- For details about how to register paper profiles, refer to [Register].

- For details about how to use paper profiles, refer to below.

- Edit or delete: [Reg./Del. Paper Set.] Screen or [Reg./Del.PaperSet.]

- Recall the paper profile: [Recall] or [No. Recall]

Adjusting Image Positions for Each Job

To increase the finishing accuracy even more, adjust the image position for each job. The procedure may differ depending on the operating environment. Use the correct procedure for the task at hand. For details about the various functions, refer to the reference page.

- Adjusting Using the System

Function | Description |

|---|---|

Adjusts for any misalignment of the printing positions on the front and back sides. | |

When the original image is larger than the actual printing area, set the original image position on paper so that the required part is printed. This allows for the required section to be printed on the paper without having to change the size of the original image. | |

Makes adjustments by shifting the position of printed images on the printing surface. |

- Adjusting Using the Application

Adjust the image position for individual jobs using the application via a computer connected to the system over a network.

Target Application | Function | Description |

|---|---|---|

AccurioPro Print Manager | Adjusts the position of printed images on the front and back sides. |

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.