Adjustment: Image quality

About Adjusting the System's Image Quality

Issues may arise during printing which mean that the intended colors cannot be reproduced on the system.

Issues with color reproducibility can occur because of changes in the system's ambient temperature or humidity, changes in the system's condition, or changes in the type of paper being used.

Perform "Image Quality Adjustment" regularly in order to maintain stable image quality.

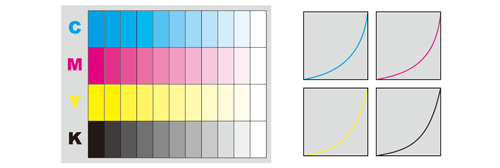

"Image Quality Adjustment" is a process for making adjustments so that you can reproduce the intended color on the system. It allows you to adjust the input/output curve for each CMYK color in the image so that you can get closer to the desired color.

What is the Image Stabilizing Control Function?

The system includes an automatic function called the "Image Stabilizing Control Function" that helps you to make image quality adjustments.

Having the user make adjustments to the image quality each time they perform a task can be a waste of time and resources. The Image Stabilizing Control Function reduces the need for such work, stabilizing the image quality to a preset standard.

The Image Stabilizing Control Function allows the system to make a variety of automatic corrections when conditions that require image stabilizing type corrections are detected. The items that can be corrected are described below.

Because the corrections are not made with use of charts, factors such as the paper type and characteristics, or whether it was transferred or fused, are not taken into consideration.

In order to perform adjustments and corrections to the image quality at higher accuracies, the user should make the image quality adjustments themselves.

Item | Description |

|---|---|

Long correction control | Corrects for changes in image output density that occur as a result of the system not being used for long periods, changes in the ambient humidity, or when printing large volumes. |

Image stabilization control | Corrects for changes in output density and line width that occur when making multiple consecutive prints. |

Middle correction control | When changes occur that cannot be corrected using just image stabilization control, the correction values of each correction function are reconstructed. |

Color registration correction control | Corrects for main scan, sub scan, horizontal magnification, and skew deviations. |

Performing Image Quality Adjustments

In order to maintain color reproducibility, it is recommended to perform the adjustment workflow detailed below using the system.

The operations may differ depending on the options mounted on the system. For details about the operating procedures, refer to the reference page.

Adjustment Workflow/Reference | Description | |

|---|---|---|

Adjustment that should be performed by all end users during day to day use. Perform the adjustment at the following times: After powering on When outputting 1,000 to 2,000 copies* Just before outputting jobs for which color is important Elsewhere, if you feel the color seems strange | ||

Perform these adjustments in cases such as those below, or when the required image quality cannot be obtained, even after performing the daily adjustment workflow (standard). Just before outputting jobs for which color is important When color stability is not sufficient (when you want to improve the accuracy of reproducibility) When the paper type is different | ||

Check the color reproducibility after adjusting image quality | Perform after adjusting the image quality. | |

Check the status of the system when there are issues in the image quality | Perform if an abnormality is found in the image. | |

Make the adjustments in circumstances such as those detailed below. When using a new type of paper When you cannot reproduce colors even after performing the daily adjustment flow (high accuracy) | ||

Perform when you want to change the screen to be used for printing. | ||

*Adjustments are performed automatically if Relay Unit RU-518m is mounted, and therefore no action needs to be taken.

The recommended workflows for performing Image Quality Adjustment at the correct timings is detailed below.

Timing | Adjustment Workflow |

|---|---|

Perform every day | |

Perform every 2 to 3 months | |

Perform at user discretion 1. When the paper type has changed 2. When printing 1,000 to 2,000 copies *1 3. When the screen has changed | |

Perform when making further finishing adjustments after executing a job *2 1. When making adjustments while referring to the print results 2. When making adjustments to the overall color 3. When using a spot color for specific sections within a job 4. When swapping out certain colors within print jobs with replacement colors 5. When you want to stabilize color reproducibility |

*1 Adjustments are performed automatically if Relay Unit RU-518m is mounted, and therefore no action needs to be taken.

*2 You can also adjust the color and image quality during printing using the printer driver and AccurioPro ColorManager.

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.