IDC Sensor Adjustment: Correcting the IDC Sensor

The printer gamma correction is periodically and automatically made on this machine. The automatic gamma correction uses an IDC sensor to scan the pattern. Should the IDC sensor be change in characteristics, the automatic gamma correction may not be performed properly. The IDC Sensor Adjustment allows you to correct the IDC sensor using the scanner, in order to make the gamma correction properly.

Make this adjustment after completing the Gamma Automatic Adjustment.

Use plain paper or white paper for color printing in this adjustment. Using colored paper cannot make this adjustment properly, affecting the color of output test pattern.

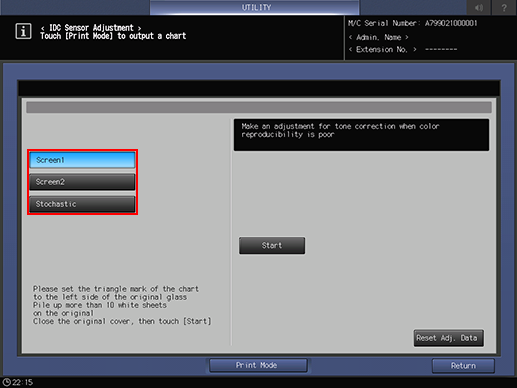

To restore to the measured data of the ROM, press [Reset Adj. Data] to reset it.

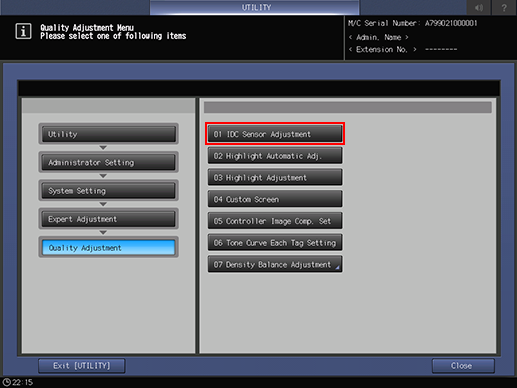

Follow the procedure on Administrator Setting to display the [Administrator Setting Menu] screen.

Press [System Setting] on the [Administrator Setting Menu] screen, and then press [Expert Adjustment], [Quality Adjustment], and [IDC Sensor Adjustment] in sequence.

The [IDC Sensor Adjustment] screen is displayed.

Select the screen to be adjusted.

The screens provided here are the same as those provided in the Highlight Adjustment.

To clear the colorimetric data currently set on the machine and restore the data in ROM, press [Reset Adj. Data]. Press [Yes] on the dialog. Or, press [No] to cancel resetting the data.

Press [Print Mode].

The [PRINT MODE] screen is displayed.

Select A4

paper, then press Start on the control panel.

paper, then press Start on the control panel.A test pattern is printed, and the screen automatically returns to the [IDC Sensor Adjustment] screen.

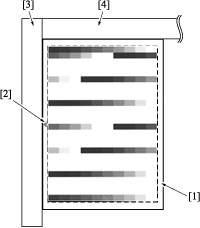

Place the test pattern on the original glass.

Position the arrow mark [2] of test pattern [1] at left, and face the print side downward.

Carefully align the test pattern [1] to the vertical original size guide [3] and horizontal original size guide [4] on the original glass.

Place about 10 sheets of blank copy paper on top of the test pattern [1].

Close the ADF.

Press [Start] on the screen, or Start on the control panel. The machine starts the adjustment automatically.

If any problem is found, an error code will be displayed to indicate the cause for each. Consult the following table to fix the errors.

Error code

Error

Remedy

Error 1

Register marks cannot be detected

Reset the chart in the correct position.

Error 2

Chart is positioned upside down

Reset the chart in the correct position.

Error 3

Pattern of chart cannot be detected

Use the correct chart.

Error 4

Adjustment is unavailable

Contact your service representative.

Error 5

Out of standard range

Make the readjustment.

Error 6

Nonvolatile data error

Check the installation of memory board.

Error 7

Accessed undesignated memory

Contact your service representative.

Error 8

Error related to memory

Contact your service representative.

Error 9

Program error

Contact your service representative.

Error 10

Chart is skew

Use the correct chart.

Error 11

Failed in scanning the image header information

Contact your service representative.

Error 12

RGB data error

Check that the chart is correct, and contact your service representative if any solution can be found.

Error 13

Parameter setting error

Contact your service representative.

Error 31

Abnormal sensor data

Make the readjustment.

Error 51

Regression calculation error

Make the readjustment.

Error 52

Array number overflow

Contact your service representative.

Error 53

Regression order error

Contact your service representative.

Error 54

Selected screen information error

Contact your service representative.

Error 55

Color information error

Contact your service representative.

Repeat steps 4 to 7 until the message [Completed] is displayed.

Press [Return] to return to the [Quality Adjustment Menu] screen.