Registration Adjustment: Adjusting Paper Loop of Registration Roller

If the punch position is not parallel to the paper edge for output, control paper curling and wrinkling by adjusting the paper loop of the registration roller in Punch Kit PK-522 mounted on Finisher FS-532.

Objects of adjustment: Back on Top Output, ADU Feed

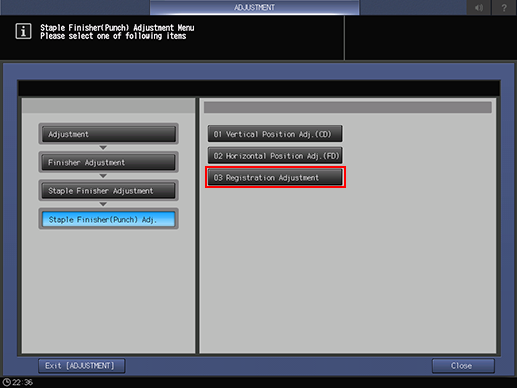

Press [Adjustment] on the [MACHINE] screen to display the [Adjustment Menu] screen.

Press [Finisher Adjustment], [Staple Finisher Adjustment], [Staple Finisher(Punch) Adj.], and [Registration Adjustment] in sequence.

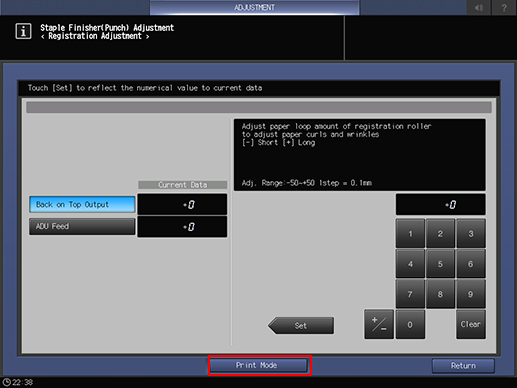

Select [Back on Top Output] or [ADU Feed].

Press [Print Mode].

Load the desired paper into a tray, then select that tray.

For [Output Setting], [Punch] is automatically selected.

Press Start on the control panel.

A sample pattern will be output.

Check if the punch holes are skew on the printed paper.

Press [Exit PrintMode] to return to the [Registration Adjustment] screen.

If any adjustment is required, use the touch panel keypad to enter the set value.

Adjustment Range: -50 ([Short]) to +50 ([Long]) (1 step = 0.1 mm)

Press [+/-] to specify the value to be positive or negative.

Press [Set] to change the setting with the Current Data.

Repeat steps 4 to 10 until the desired result is obtained.

Press [Return].

The screen returns to the [Staple Finisher(Punch) Adjustment Menu] screen.